Optimize your Petrochemical Process in all Stages

In petrochemical processes, the need to reduce downtime, minimize corrosion, reduce waste and the use of chemicals is ever present. The value of process analytics in these environments is substantial. optek provides top-quality solutions for photometrical, and electrochemical inline analyses in refineries and other petrochemical industries. Our products are designed for chemical extremes and high temperatures and are certified for use in hazardous areas.

Color of Refined Fuels

…The petroleum refining and petrochemical industries rely on Saybolt and ASTM color scales (among others) to quantify product quality. ASTM D1500 defines the ASTM color scale (0.0 to 8.0 ASTM) and is u…

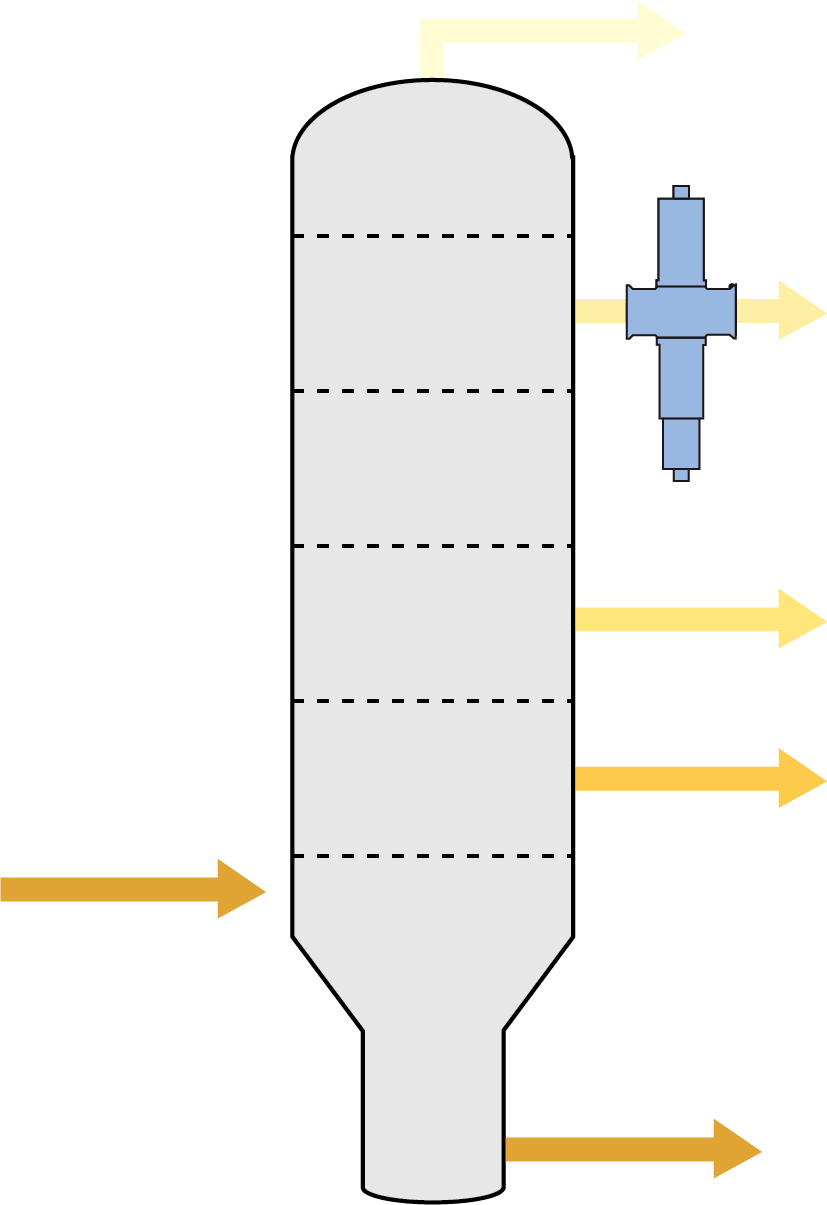

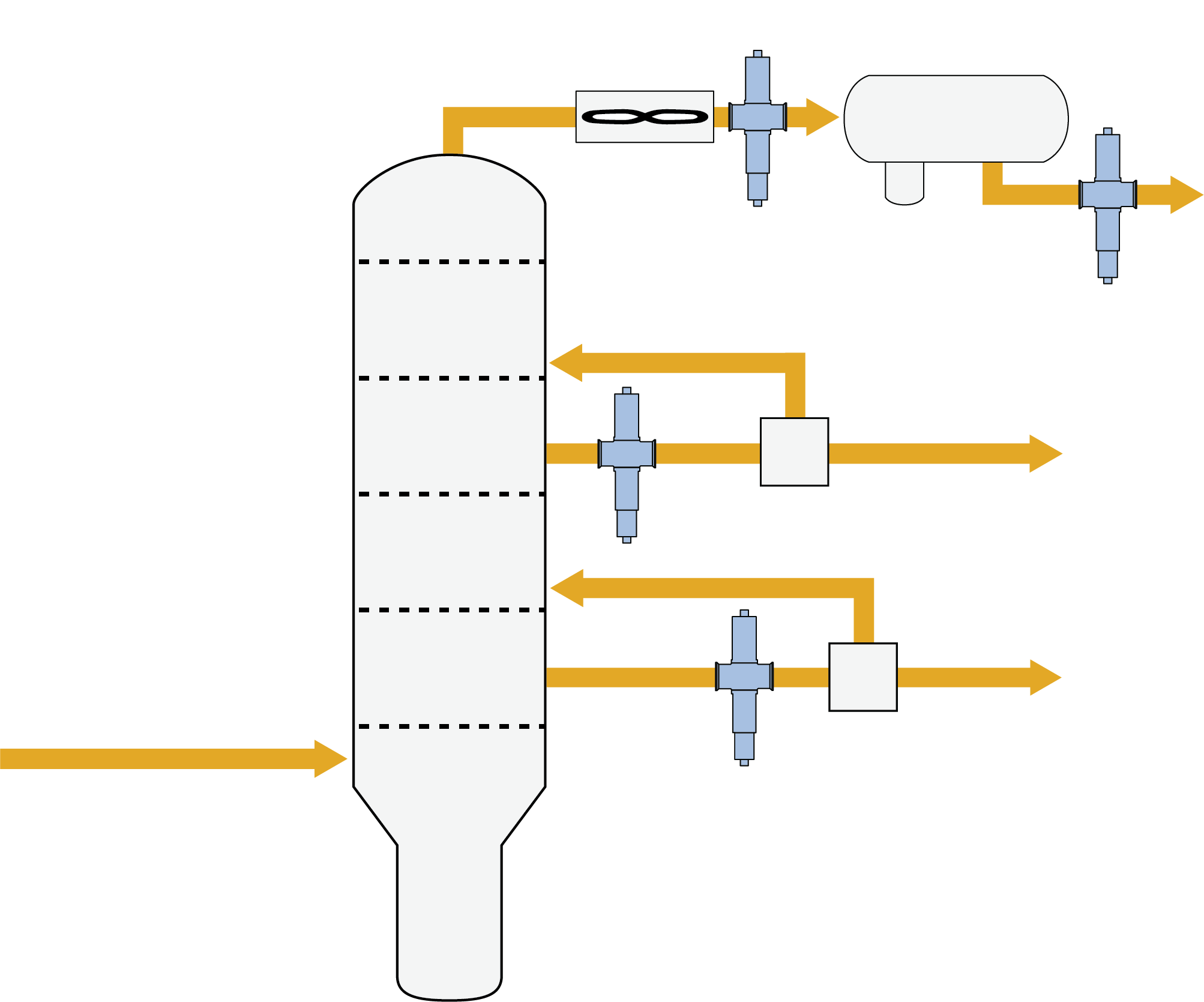

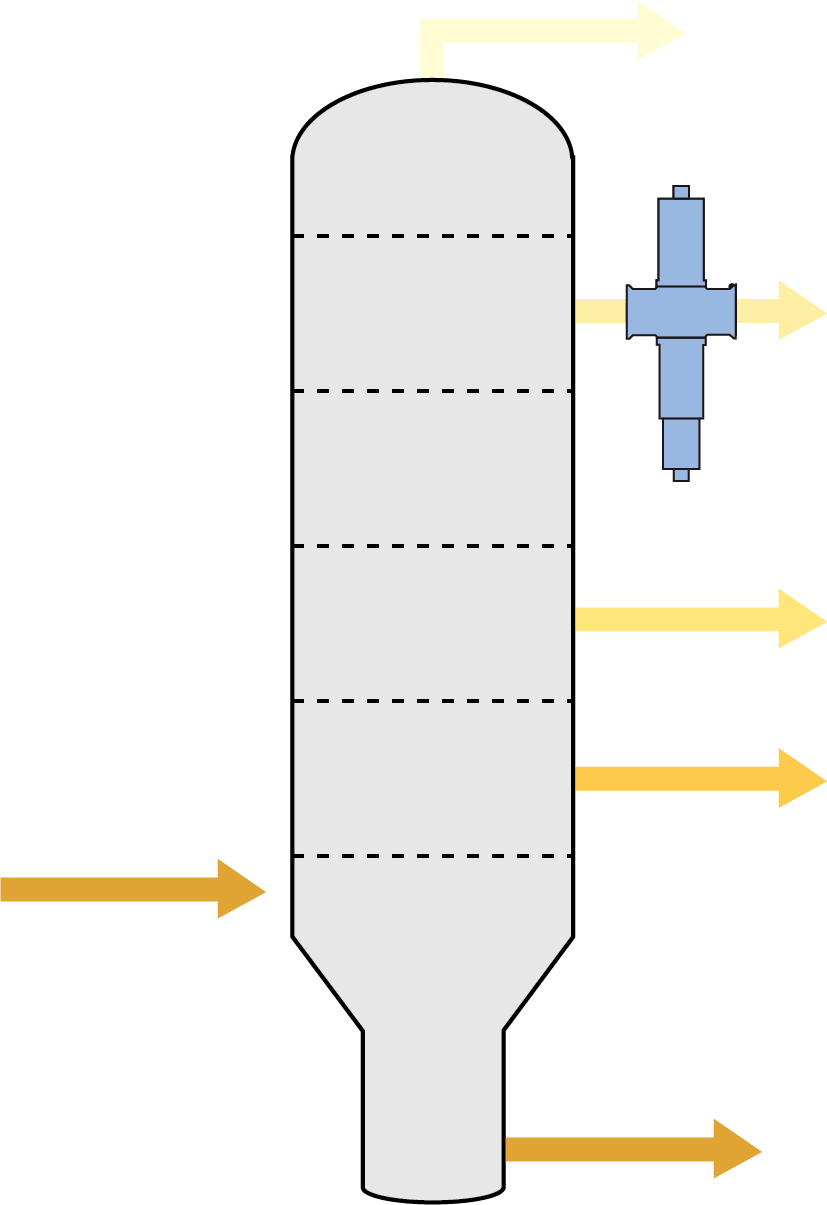

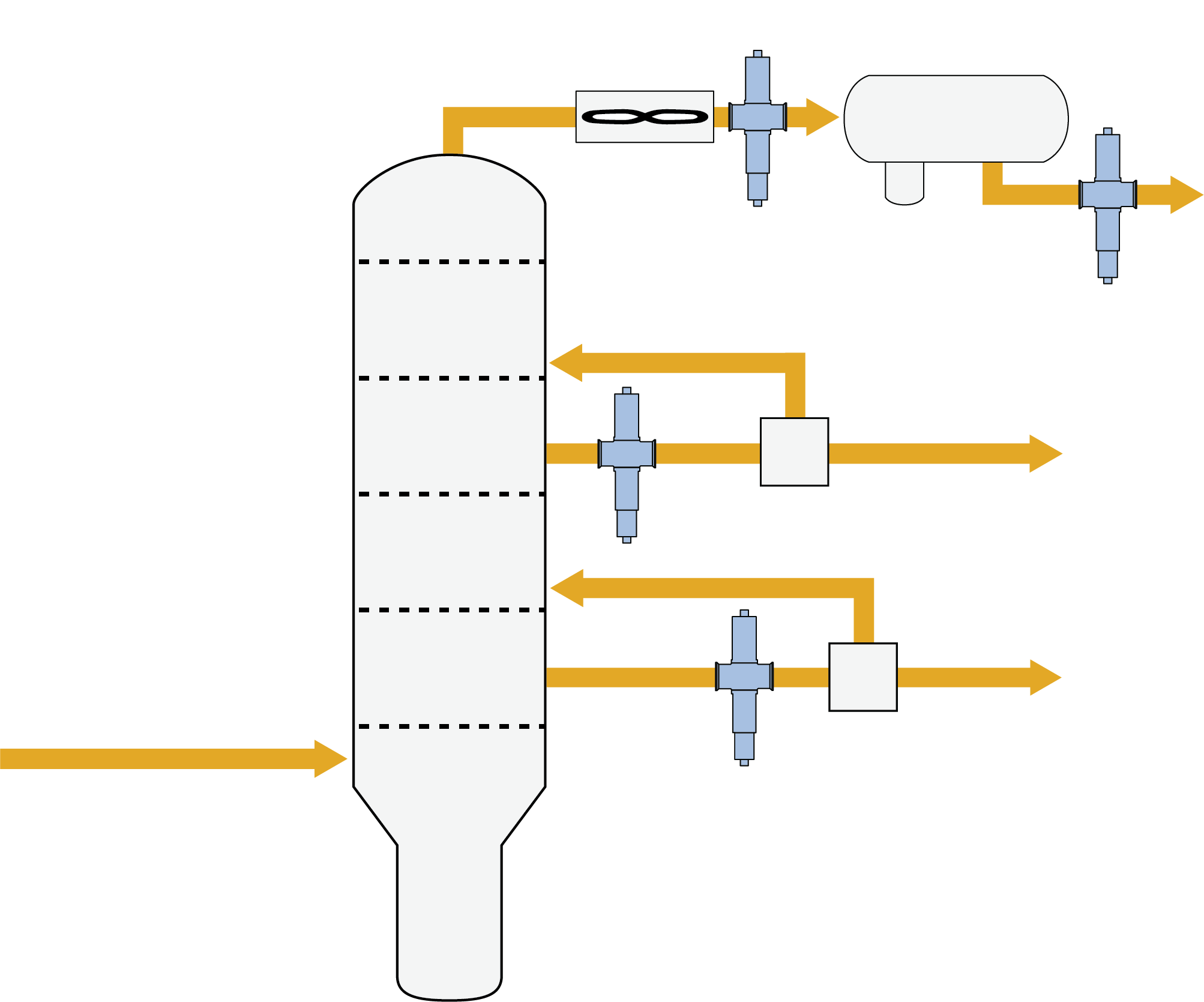

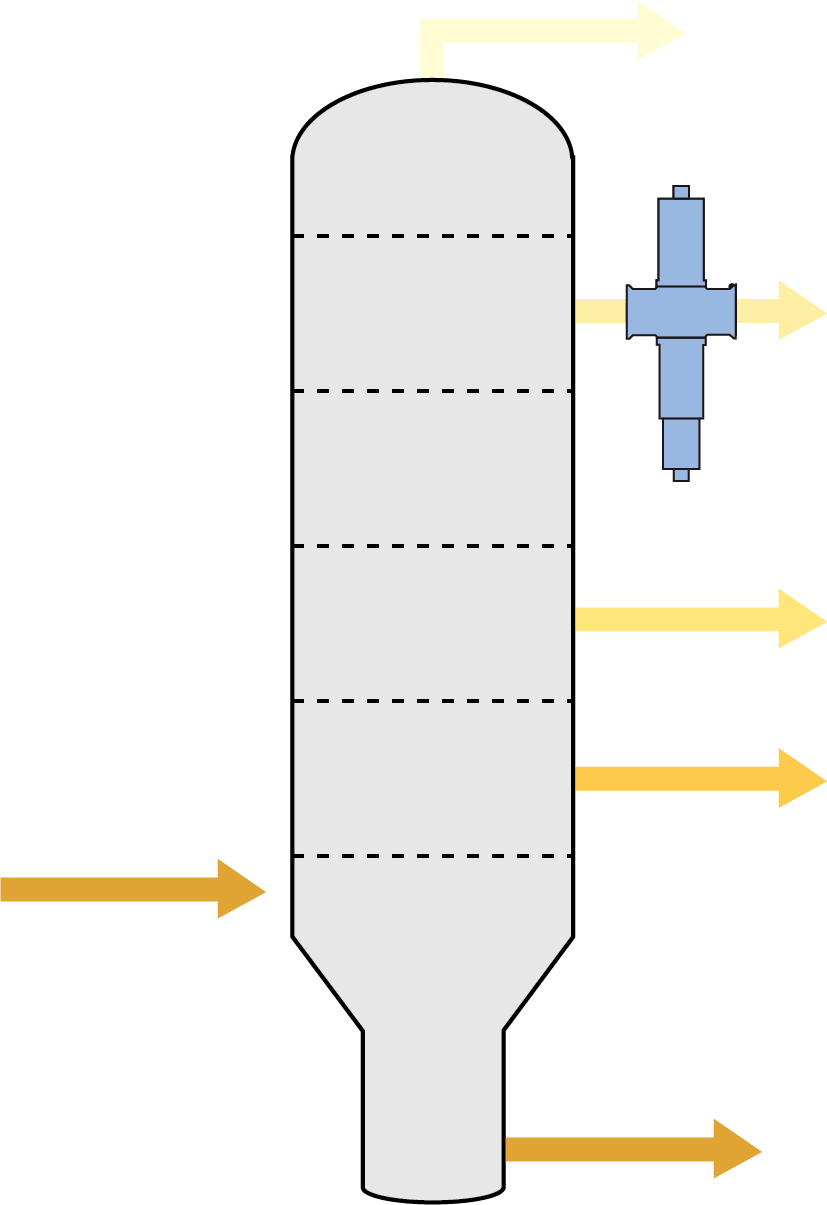

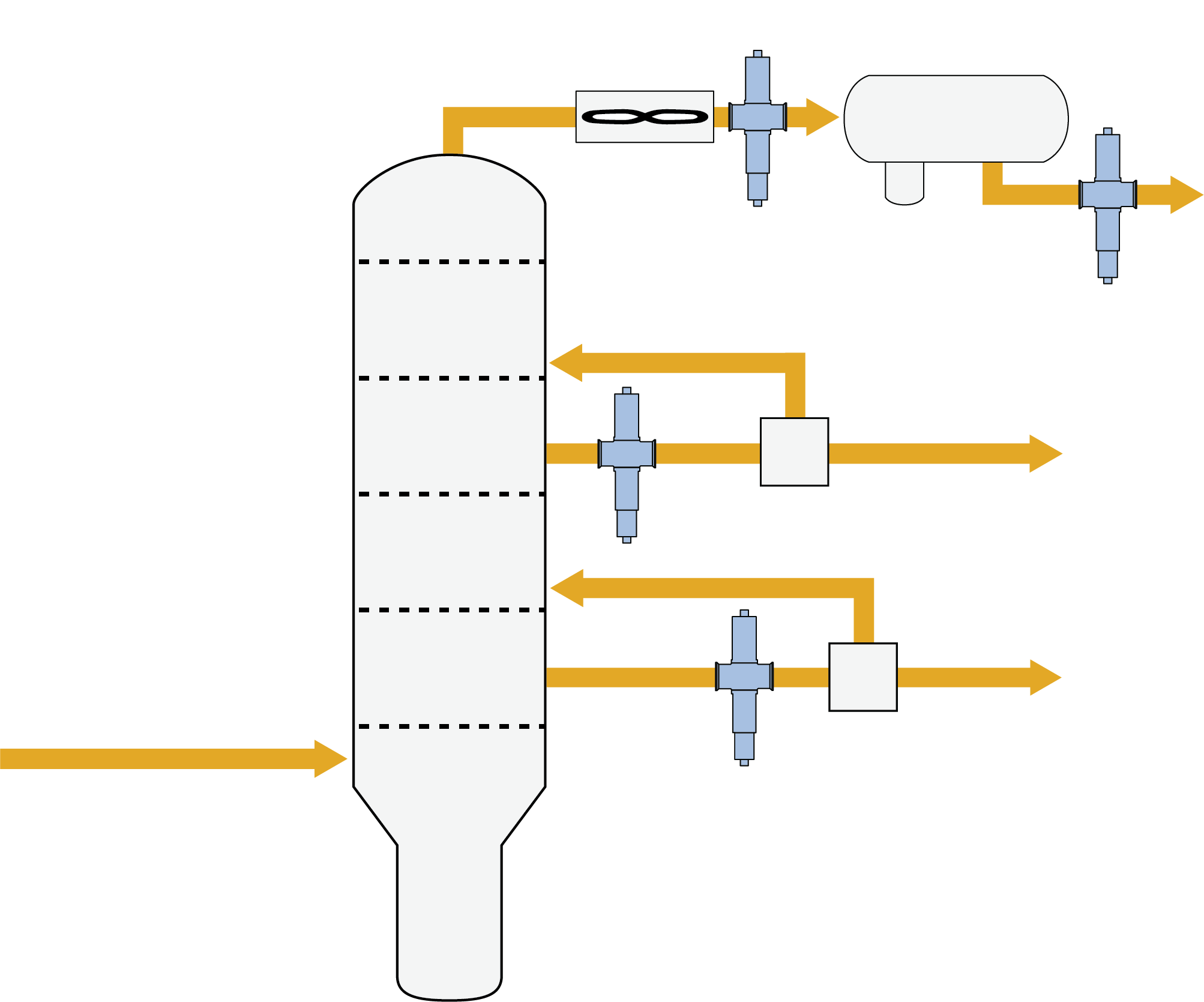

Crude Distillation Unit (CDU) Monitoring

…Naphtha, gasoline, kerosene and jet fuels are the lightest and highest quality hydrocarbons drawn off the top of the distillation column. Because of their low levels of impurities, they normally have …

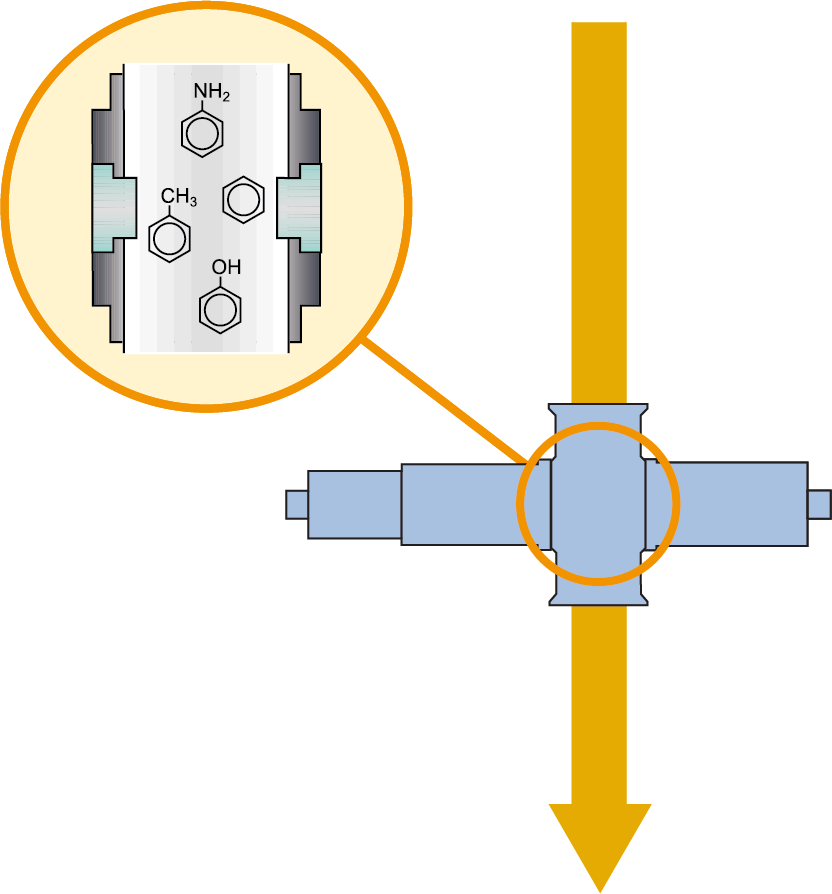

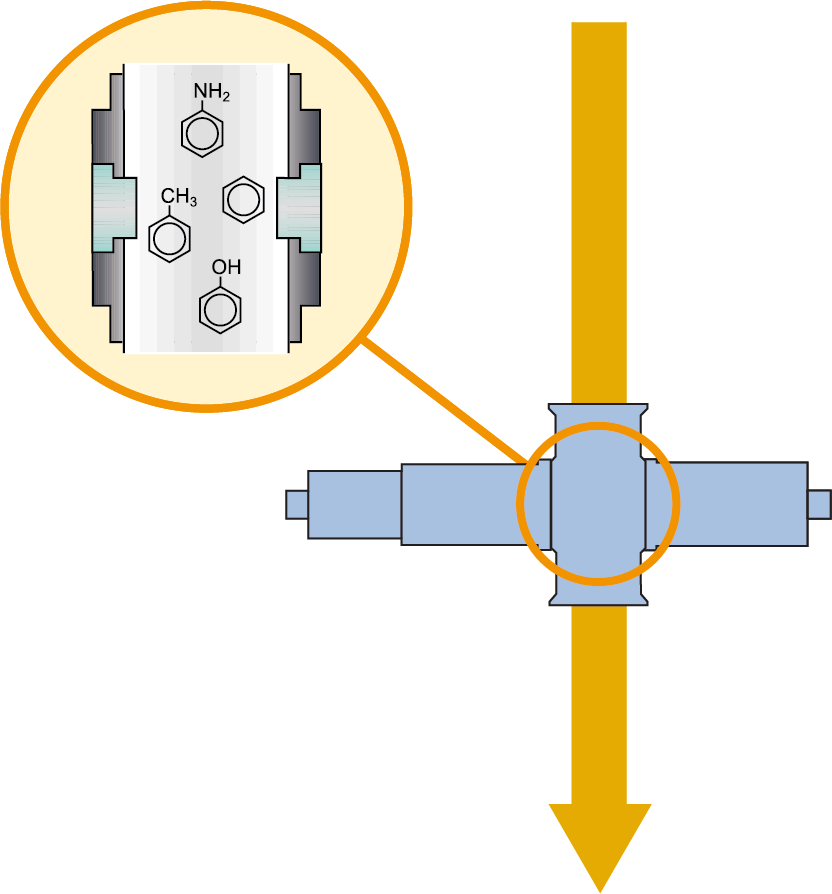

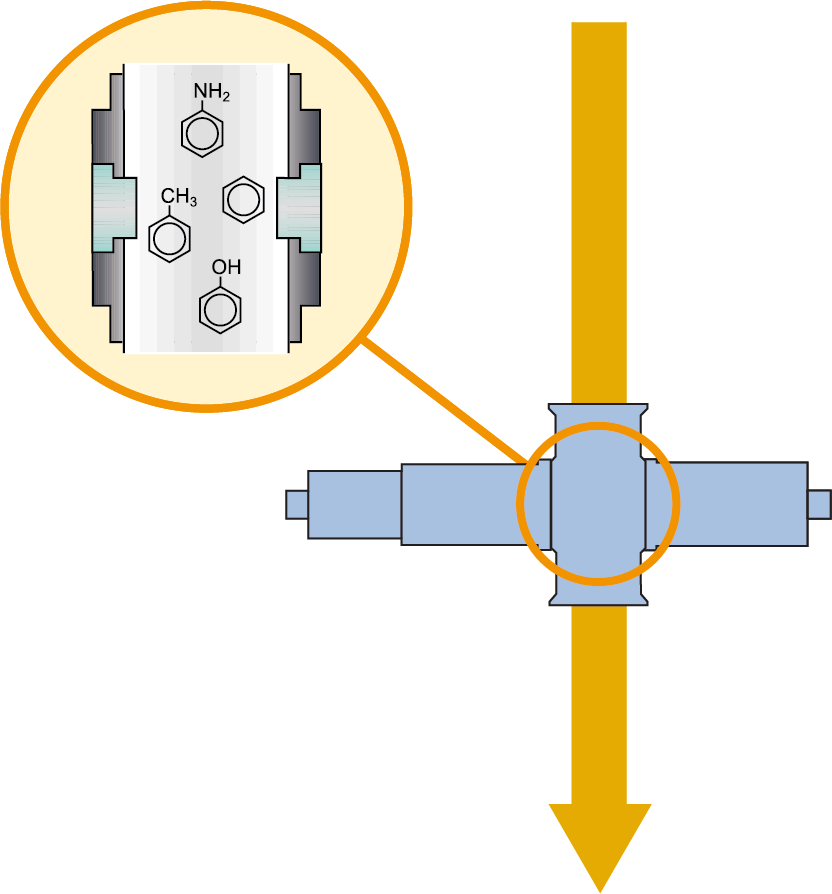

Aromatics Detection

optek has two UV absorption sensors which can make these measurements. In process streams containing background turbidity, a dual wavelength AF46 is used where one wavelength is used to detect the aro…

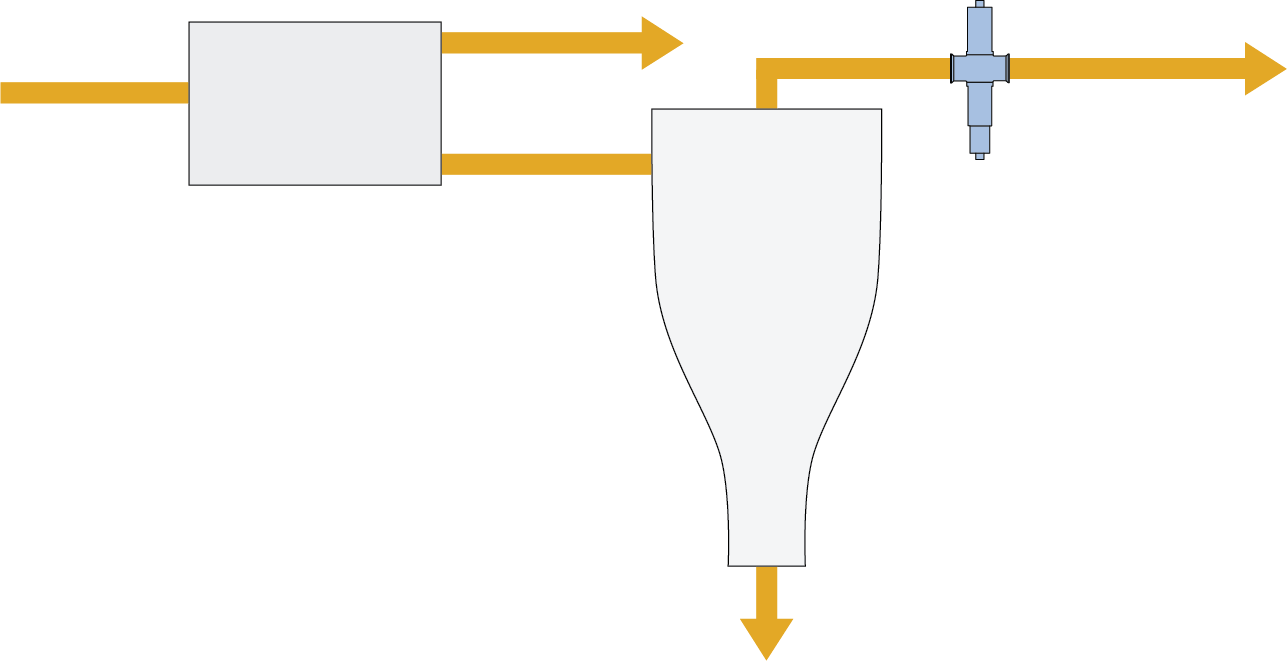

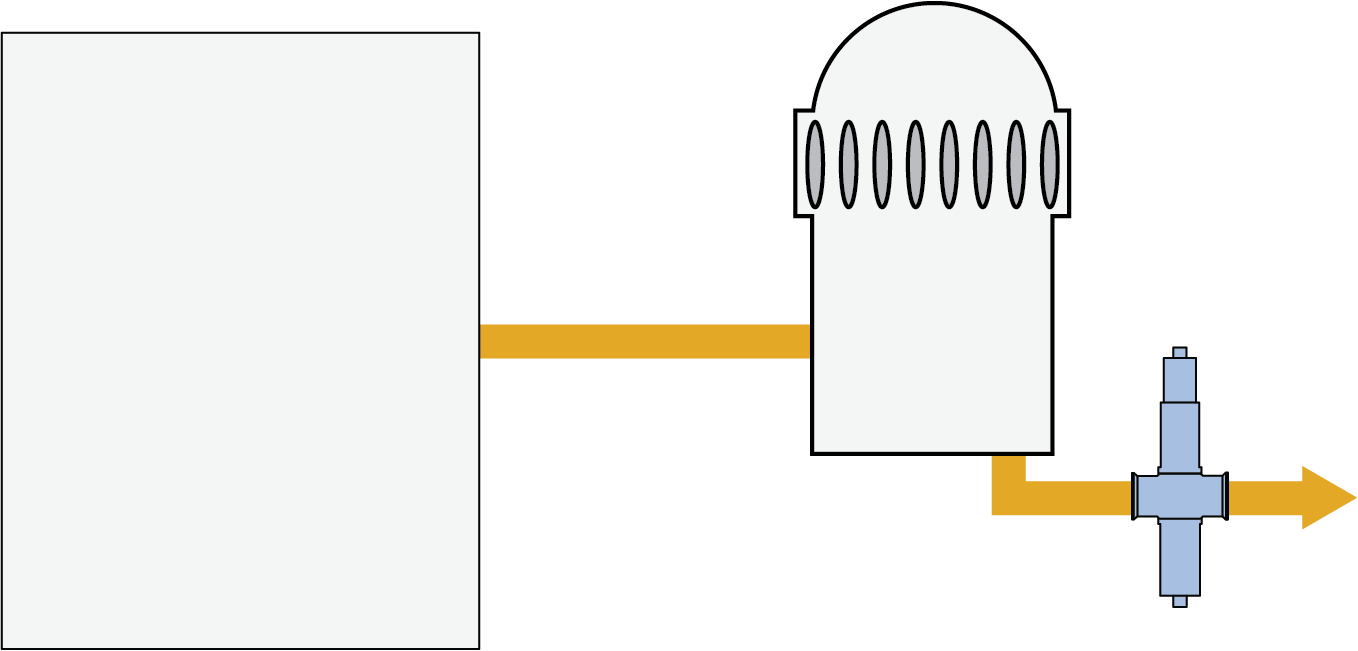

Oil in Produced Water

optek TF16-N sensors can detect very low levels of oil using scattered light technology. Because this technology is much more sensitive to oil droplets in water, it is the preferred monitoring techniq…

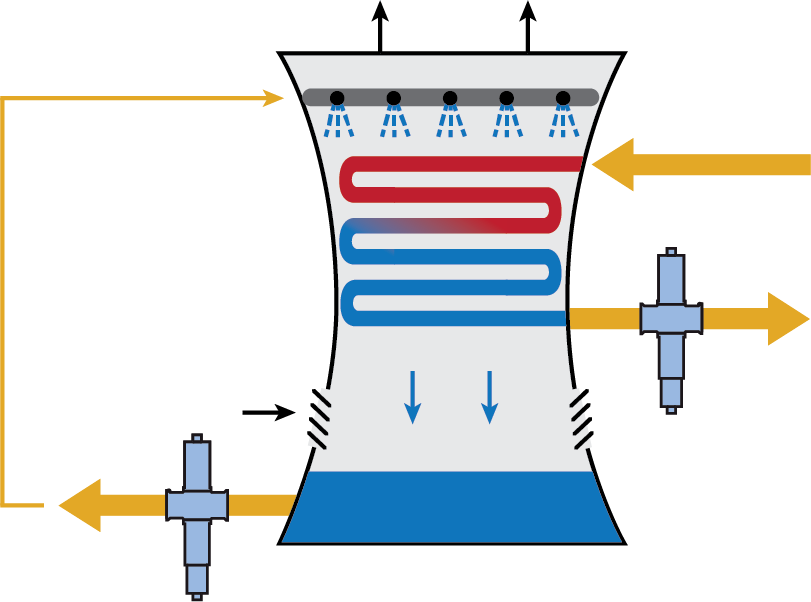

Condensate and Cooling Water Monitoring

…By using optek photometers in heat exchanger cooling/heating lines, a pinhole leak can be detected and repairs can be made before an expensive breakdown occurs. Also, operating costs are reduced becau…

Fuel Analysis: Water in Fuel

These hydrocarbon streams can be monitored in real-time under process conditions to determine if and how much free water is present, down to the ppm levels. This allows operators a unique ability to m…

Rafine Yakıtta Renk Ölçümü

The petroleum refining and petrochemical industries rely on Saybolt and ASTM color scales (among others) to quantify product quality.

Ham Distilasyon Birimi (CDU) İzleme

Naphtha, gasoline, kerosene and jet fuels are the lightest and highest quality hydrocarbons drawn off the top of the distillation column.

Aromatik Tespiti

optek has two UV absorption sensors which can make these measurements. In process streams containing background turbidity, a dual wavelength AF46 is used where one wavelength is used to detect the aro…

Rafine Yakıtta Renk Ölçümü

The petroleum refining and petrochemical industries rely on Saybolt and ASTM color scales (among others) to quantify product quality.

Ham Distilasyon Birimi (CDU) İzleme

Naphtha, gasoline, kerosene and jet fuels are the lightest and highest quality hydrocarbons drawn off the top of the distillation column.

Aromatik Tespiti

optek has two UV absorption sensors which can make these measurements. In process streams containing background turbidity, a dual wavelength AF46 is used where one wavelength is used to detect the aro…